Mechanical Advantage: A system of ropes and pulleys allows heavy loads to be lifted more easily. Simple systems are readily understood. If, down a well, a bucket of water weighing 10 kg is lifted with no pulleys, there is no mechanical advantage. It is a 1:1 system; lifting 10 kg requires a force of 10 kg. Every meter that the bucket is raised requires one meter of rope to be raised too.

Adding a Pulley Block: If the standing end of the rope is now attached at the top at the top of the well and a pulley is added to the handle of the bucket, the lifting force required is half but the amount of rope used in lifting is doubled. It has become a 2:1 system. Simple systems like this are readily understood. More complicated systems can be harder to understand.

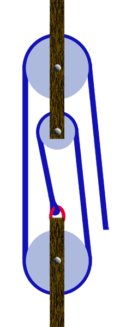

A Block and Tackle System: The arrangement of ropes and pulleys on the left could be interpreted as a 3:1 purchase or a 4:1 purchase. This is because there is no way of knowing which part moves when the end is pulled. The examples below illustrate this.

Theoretical Mechanical Advantage vs. Practical Advantage: The ratios described here are purely theoretical. Several factors prevent such ratios being realized in practice: blocks, tackle, and rope add weight; pulleys have friction; the ropes are not exactly vertical; and rope has internal friction as it bends around the blocks.

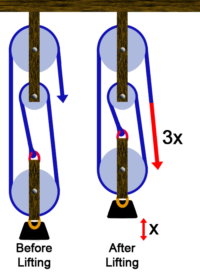

Lifting – Purchase 3:1. The left hand picture shows the tackle before lifting the weight. Three strands of rope pass down to the moving lower assembly. When the free end of the rope is pulled, by say three meters, the lower assembly rises by one meter (right hand picture). This is a 3:1 mechanical advantage. The inconvenience of handling the extra rope is offset by the advantage of the reduction in force required.

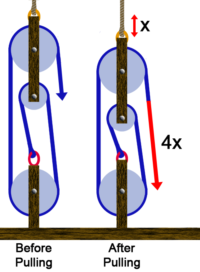

Pulling Down – Purchase 4:1. The left hand picture shows the tackle before pulling down. Four strands of rope pass up to the upper assembly, which is now the moving one. When the free end of the rope is pulled, by say four meters, the upper assembly is lowered by one meter (right hand picture) – and this is a 4:1 mechanical advantage.

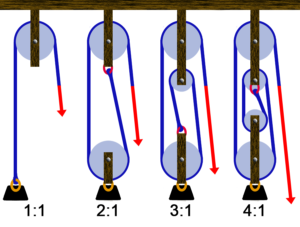

Mechanical Advantage: Four Examples. Here in one picture are four examples of lifting a weight with increasing mechanical advantage from Left to Right. All four weights have been lifted by the same amount. The length of rope used is proportional to the Mechanical Advantage.

In each case the large pulley at the top provides no Mechanical Advantage – it merely allows the rope to be pulled down conveniently. Counting the ropes reaching the bottom tackle provides the Mechanical Advantage.

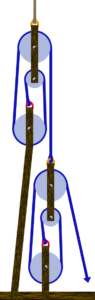

Compound Mechanical Advantage: This picture shows two sets of blocks – one above the other. Each set provides a 3:1 Mechanical Advantage. The final effect is a 9:1 Mechanical Advantage. The pulling rope has to move nine times further down than the rope at the top will move.

The increase in purchase is offset by the added complexity. In practice it is often more convenient to use sheaves with multiple pulleys.

Professional Applications. Understanding and using ropes and pulleys for mechanical advantage is of critical importance in some organizations whose members employ rope block and tackle systems, e.g., the Society of Professional Rope Access Technicians SPRAT a member- driven organization that advances the safe use of rope access through education; and the International Technical Rescue Association ITRA that promotes international best practices and standards for technical rescue. Many other US organizations are listed on Wikipedia.

Examples: Rope Access Techniques are now part of exciting International Competitions and may be seen commercially in Window Cleaning, Washing the Underside of the Grand Canyon Sky Bridge, Repairing Wind Turbine Blades, Repairing Buildings, Tree Climbing by Arborists and elsewhere.

Purpose of This Page: Rope and Pulley systems are readily misunderstood. This brief overview provides an introduction designed to show how the same arrangement of rope and pulleys provides a different mechanical advantage depending on which part moves.

Rope on Rope: Many block and tackle systems provide mechanical advantage. Some systems use rope but no pulleys, e.g., a Trucker’s Hitch. Then, useful as it is, friction means that the actual mechanical advantage falls far short of theory.